Understanding Constant Speed Propellers – How They Work and Their Benefits

What is a Constant Speed Propeller?

A constant speed propeller represents an advanced variable-pitch system that automatically adjusts blade angles to maintain consistent, pilot-selected RPM. This intelligent mechanism adapts to fluctuations in engine power, airspeed, and altitude, providing peak efficiency throughout every flight phase—from the initial takeoff surge to the final landing approach.

Particularly valuable in high-performance aircraft, these systems outperform fixed-pitch alternatives. They provide better performance, improved fuel efficiency, and smoother engine operation.

How Constant Speed Propellers Work

At their core, constant speed propellers employ an advanced hydraulic system governed by a propeller controller that adjusts blade pitch while maintaining predetermined RPM settings.

The system works on the intricate relationship between blade pitch and engine RPM. Increasing blade angle creates higher pitch, generating greater thrust but demanding more engine torque—naturally decelerating rotation. Conversely, decreasing the angle reduces torque requirements, permitting the engine to accelerate. This inverse relationship forms the foundation of the automatic control system.

Modern constant speed systems use pressurized oil flowing through hollow propeller shafts to activate pitch-change mechanisms within the hub. The propeller governor—essentially the system’s “brain”—controls this hydraulic system. Pilots simply set their desired RPM via the cockpit’s propeller control lever, while the governor maintains this setting autonomously.

The governor employs centrifugal flyweights that respond to rotational forces. As RPM fluctuates, these flyweights shift position, adjusting a speeder spring that regulates pressurized oil flow to the propeller hub.

This creates a feedback loop: rising RPM triggers the governor to increase blade pitch, adding aerodynamic resistance and moderating engine speed. When RPM drops, reduced oil pressure allows lower pitch settings, decreasing load and enabling the engine to return to its target value.

Benefits of Using Constant Speed Propellers

Constant speed propellers provide significant advantages that improve aircraft performance throughout all flight phases. While fixed-pitch counterparts excel in only one specific flight regime, constant speed systems provide peak efficiency from takeoff through landing by adapting blade pitch to evolving flight conditions.

-

Improved Fuel Efficiency: By keeping the engine at its optimal RPM, the system reduces fuel consumption and extends flight range.

-

Optimized Performance: The propeller automatically sets a low pitch for maximum power during takeoff and a high pitch for efficient cruise flight.

-

Enhanced Engine Longevity: Maintaining a consistent RPM reduces engine stress and vibration, extending its operational life and lowering maintenance costs.

-

Reduced Pilot Workload: The governor automates pitch adjustments, freeing the pilot to focus on other critical flight management tasks.

-

Greater Aircraft Stability: Consistent power delivery results in more predictable aircraft handling, which is especially important during approach and landing.

Feathering and Emergency Procedures

Feathering represents a vital safety feature in multi-engine aircraft. During engine failure, the affected propeller generates substantial drag as airflow forces continued rotation—a destructive phenomenon called windmilling.

To address these problems, pilots activate the feathering mechanism, rotating propeller blades until their edges align parallel with airflow. This streamlined configuration reduces drag while preventing windmilling, enabling the aircraft to maintain better control and performance on remaining engines. Often, this drag reduction determines whether a twin-engine aircraft can sustain altitude on single-engine power.

Most constant speed systems accomplish feathering through hydraulic or mechanical means. Typically, positioning the propeller control to “feather” channels oil pressure to rotate blades toward maximum pitch. Pilots must understand a critical vulnerability: oil pressure loss during engine failure may trap the propeller in a low-pitch, high-drag configuration—the worst possible scenario during emergency conditions.

Therefore, emergency procedures emphasize immediate propeller feathering on failed engines. Pilots undergo extensive training on these procedures since the window for effective action can be very short. Many aircraft incorporate dedicated feathering buttons or specialized control positions that rapidly drive propellers to feathered positions, bypassing normal governor systems. Advanced variants even feature auto-feathering capabilities that detect engine failures and execute feathering without pilot intervention.

Regular emergency procedure practice is crucial for multi-engine pilots. Quick, decisive action often determines the difference between maintaining controlled flight and losing aircraft control entirely.

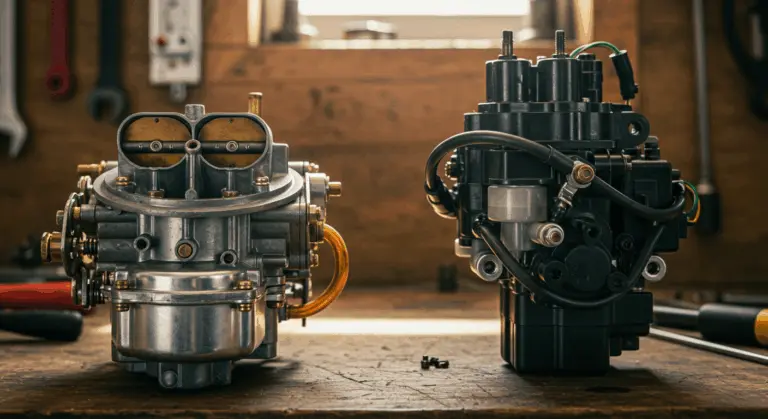

Comparing Constant Speed and Fixed Pitch Propellers

When evaluating propeller systems, the distinction between constant speed and fixed pitch represents a fundamental choice affecting performance, efficiency, and operational complexity. Fixed pitch propellers maintain unchanging blade angles throughout all operations. This simple design limits peak performance to one specific flight phase—typically takeoff, cruise, or climb—creating inevitable compromises elsewhere.

Consider this: a fixed pitch propeller optimized for cruise delivers excellent efficiency at specific airspeeds and power settings but struggles during takeoff and climb phases. Conversely, one designed for maximum takeoff thrust sacrifices cruise efficiency. This built-in limitation creates a performance limit that pilots must accept.

Constant speed propellers, however, adjust blade pitch for every flight phase. The result? Better climb rates, higher cruise speeds, and improved fuel economy.

Despite their mechanical sophistication, constant speed propellers remain relatively easy to operate. The primary cockpit difference involves adding a propeller control lever alongside traditional throttle and mixture controls. Most pilots master their operation within just a few instructional hours. The learning curve centers on setting appropriate RPM for various flight phases and understanding the relationship between manifold pressure and propeller RPM.

Though they command higher acquisition and maintenance costs, the significant performance benefits justify their widespread adoption in high-performance and multi-engine aircraft.

Conclusion: The Importance of Constant Speed Propellers

Constant speed propellers are important aviation technology. Their ability to automatically adapt blade pitch ensures optimal engine RPM across all flight phases, providing significant improvements in performance, fuel efficiency, and engine longevity.

This adaptability, coupled with critical feathering capabilities, makes them essential components for improving capability, safety, and efficiency in modern propeller-driven aircraft.