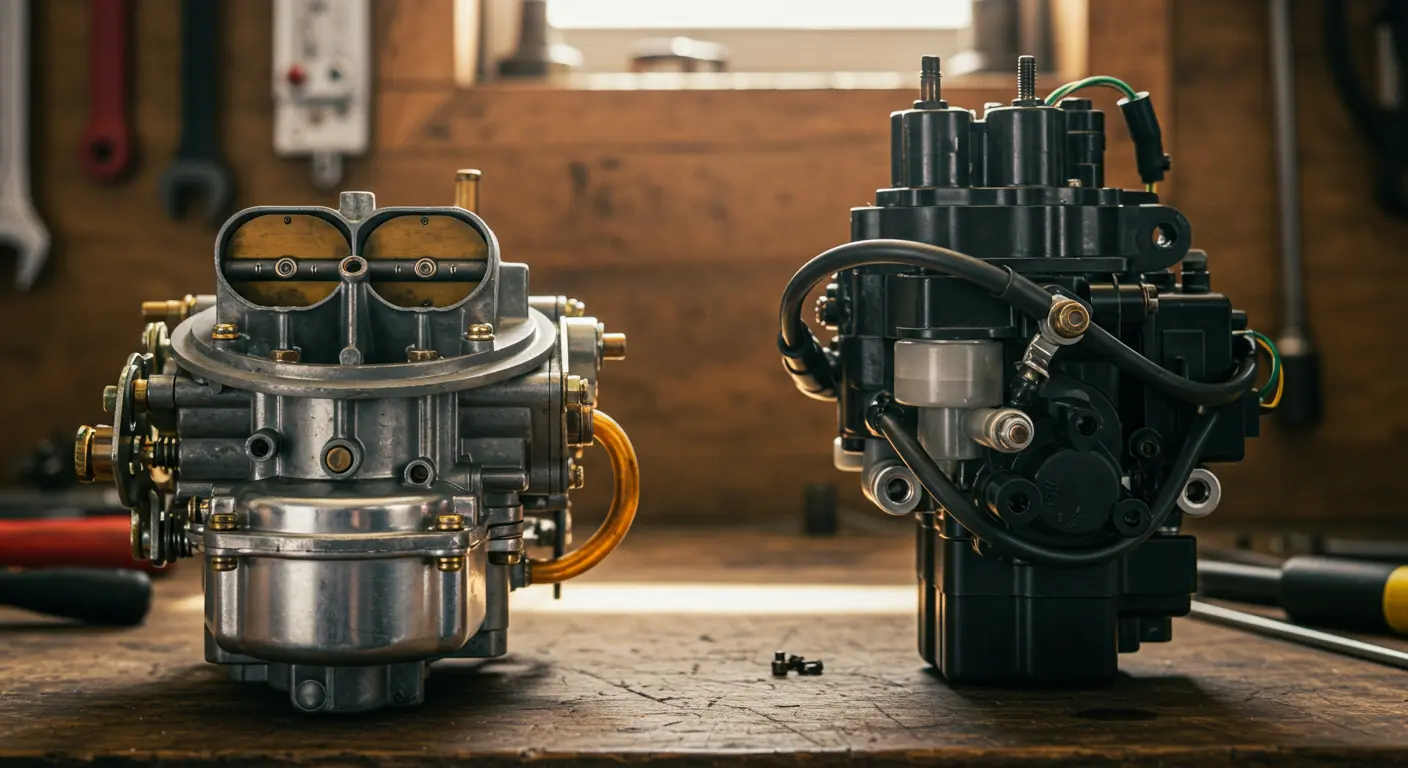

Carburetor vs Fuel Injection – Key Differences Explained

Understanding Carburetors – How They Work

The carburetor stands as a fascinating mechanical marvel that blends air and fuel for combustion in traditional engines. Unlike modern electronic systems, it operates purely on physical principles—a characteristic that makes it both elegantly simple and inherently constrained.

At its heart lies the Venturi effect: air rushing through a narrowed tube accelerates dramatically while its pressure plummets. This pressure differential creates a powerful vacuum that draws fuel into the rushing airstream.

Two critical valves control the carburetor’s air and fuel mixing process.

Fuel flows through precisely calibrated jets. As the throttle opens wider, increased airflow generates a stronger vacuum, drawing more fuel into the mixture to maintain a reasonably consistent air-fuel ratio—though with considerably less precision than modern fuel injection achieves.

Despite their effectiveness, carburetors face a fundamental challenge: maintaining optimal air-fuel ratios across varying engine speeds and conditions. This limitation becomes evident during rapid throttle changes or when confronting different altitudes and temperatures, where their fixed mechanical design simply cannot adapt as dynamically as electronic systems.

Advantages of Carburetors

-

Mechanical Simplicity: With no electronic components, carburetors are reliable and easier to repair with basic tools, making them ideal for classic cars and off-road vehicles.

-

Cost-Effectiveness: They are cheaper to manufacture, install, and repair. Parts are generally affordable, and many fixes require only basic mechanical knowledge.

-

High-Performance Potential: Many racing applications favor carburetors because they can deliver large volumes of fuel quickly at wide-open throttle, maximizing power.

-

Lightweight Design: Carburetors are significantly lighter than fuel injection systems, a crucial advantage in aircraft and racing where power-to-weight ratios are critical.

-

Mechanical Transparency: Their operation can be observed, understood, and adjusted without specialized computers, offering a hands-on connection that many enthusiasts value.

Disadvantages of Carburetors

-

High Emissions: Imprecise fuel metering results in incomplete combustion and higher levels of harmful emissions, making them unable to meet modern environmental regulations.

-

Susceptibility to Icing: In cold, humid conditions, moisture can freeze in the venturi, blocking fuel flow and potentially causing engine failure.

-

Poor Adaptability: They require manual recalibration to compensate for changes in altitude and temperature, leading to suboptimal performance in varied environments.

-

Inconsistent Fuel Delivery: Carburetors struggle to maintain an ideal air-fuel ratio, often running too rich (wasting fuel) or too lean (risking engine damage).

-

Technological Obsolescence: A decline in available parts and technician expertise makes carburetor-equipped vehicles increasingly difficult to service.

Fuel Injection Systems – An Overview

Fuel injection represents a significant advancement over carburetors, delivering precisely measured fuel directly into the intake manifold or combustion chamber with exceptional precision.

An Electronic Control Unit (ECU) serves as the system’s brain, orchestrating a sophisticated network of sensors that continuously monitor critical engine parameters—temperature, throttle position, oxygen levels, and more.

The ECU processes this constant stream of data instantaneously, commanding injectors to deliver precisely metered fuel that atomizes perfectly for optimal combustion. The system adapts automatically to changing conditions without human intervention.

Advantages of Fuel Injection

-

Improved Fuel Economy: By precisely metering fuel for all operating conditions, FI systems significantly improve mileage over carburetor engines.

-

Lower Emissions: More complete and efficient combustion reduces harmful emissions, helping vehicles meet strict environmental standards.

-

Superior Adaptability: The system automatically adjusts to changes in altitude, temperature, and engine load, providing consistent performance without manual tuning.

-

Greater Reliability: Modern FI systems have fewer mechanical parts that wear out, require less frequent maintenance, and are less affected by vibration or engine flooding.

Disadvantages of Fuel Injection

-

Higher Cost: Sophisticated electronic components, sensors, and high-pressure parts increase manufacturing and installation costs.

-

Complex Repairs: Diagnosing and fixing problems often requires specialized diagnostic tools and trained technicians, resulting in higher repair bills.

-

Electronic Vulnerability: A failure in the ECU or a key sensor can disable the entire system, often requiring professional service.

-

Fuel Quality Sensitivity: The fine nozzles of fuel injectors are susceptible to clogging from dirt or poor-quality fuel, which can impair performance.

-

Difficult Performance Tuning: Modifying an FI system for significant power gains is typically more complex and expensive than tuning a carburetor.

The reliability debate between carburetors and fuel injection shows an interesting contrast between mechanical simplicity and electronic sophistication.

Fuel injection systems reverse this relationship. While electronically complex, they typically deliver superior long-term reliability with minimal maintenance intervention.

Environmental factors significantly affect maintenance requirements for both systems, but in strikingly different ways.

From a long-term ownership perspective, fuel injection typically offers lower total maintenance costs despite its higher initial complexity.

Fuel Economy – Which is Better?

In the fuel economy battle, fuel injection systems consistently outperform carburetors—for several clear reasons.

The real-time adjustment capability of fuel injection systems is especially important for fuel economy.

Carburetors, by contrast, operate on fixed mechanical principles that cannot adapt to changing conditions without manual intervention.

The fuel economy difference is most noticeable during cold starts and warm-up periods.

Reliability and Maintenance Considerations

When evaluating long-term ownership experiences, reliability and maintenance requirements become the deciding factors that separate carburetor and fuel injection systems.

Environmental factors significantly impact carburetor reliability, often in frustrating ways.

Fuel injection systems demonstrate superior reliability in varying conditions thanks to their electronic adaptability.

Fuel injection’s complexity does introduce potential vulnerabilities, particularly in the electronic components and sensors that enable its precision.

For specific applications—classic cars, vintage motorcycles, or simple utility engines—carburetors remain popular due to their cost-effectiveness, ease of field repairs, and compatibility with older vehicle designs.

Conclusion – Choosing the Right System for Your Needs

The choice between carburetor and fuel injection ultimately depends on matching the technology to your vehicle’s application and your personal priorities.

For classic cars or simple utility engines, a carburetor’s mechanical simplicity, lower cost, and ease of repair offer clear benefits.

For reliable daily driving, however, fuel injection is the clear winner—offering consistent performance, superior fuel economy, and lower emissions through automatic adaptation to changing conditions.

While some racing applications still favor carburetors for their simplicity at full throttle, fuel injection has become mandatory for any vehicle that must meet modern emissions standards.